Application Principle :

PTC thermistors are ideal as heating elements because of their specific R/T characteristic. The positive R/T characteristic means that electric power consumed is automatically adapted to the ambient thermal conditions. If the ambient temperature is significantly higher than Tref or heat transfer is restricted, the resistance of the thermistor rises rapidly and power consumption is limited to a very low value. Thanks to these self-regulation properties, heating devices based on PTC thermistors can generally dispense with control and regulating components as well as overtemperature protection.

PTC heating elements have the following advantages:

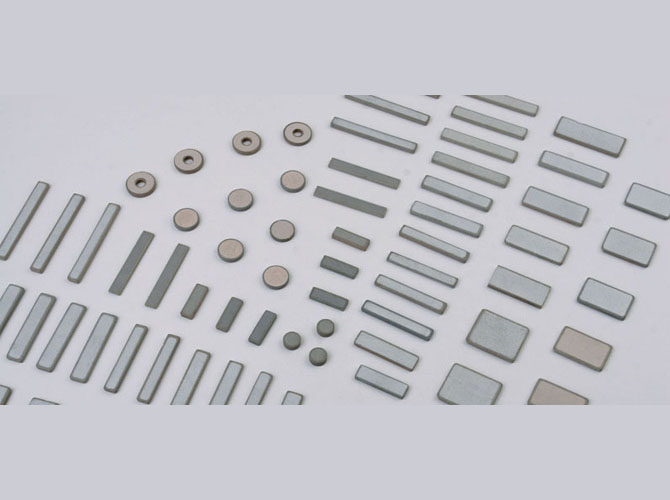

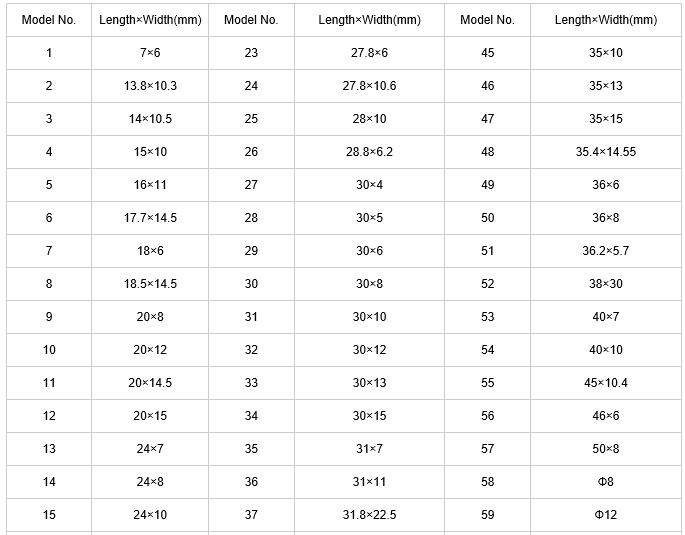

Application examples for heating thermistors:

Automotive

Domestic

Others

Notice in appliance :

1) The temperature of PTC heating element can be controlled by itself, and without the temperature control system.

2) It can be used for heating liquid, and it’s no problem when liquid was dried.

3) It can be used for heating air with fan blowing, and it’s no problem when the fan did not operate.

4) There are four electrodes coating to be selected: neckel+silver,melt-jet aluminum, screen print aluminum, screen print aluminum+silver.

5) Very long life, 10 years or longer is possible.

6) Very high reliable, over temperature was impossible.

7) Very large working voltage range.The surface temperature increases (or decreases) about 8℃, when working voltage increases (or decreases) 2 time.

8) If customer need the PTC with wire, insulator, or shell. please select other types manufactured by our company.

9) Parallel connection is necessary for two or more PTC connection.

10) The power may be very different with different applied condition for same PTC. The faster is the heat conduction, the higher is the power

Universal technical data of PTC thermistor :

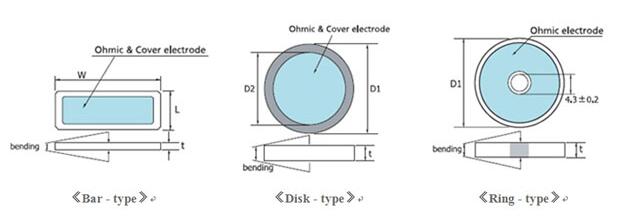

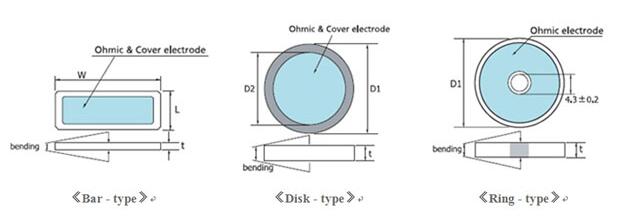

Structure chart

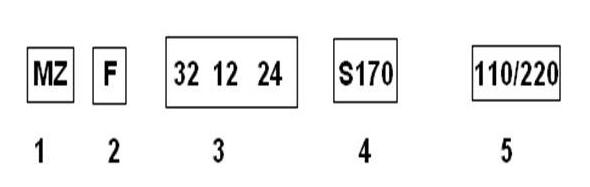

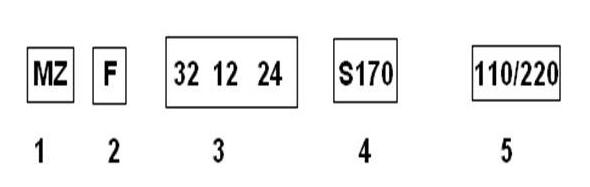

Type Designation

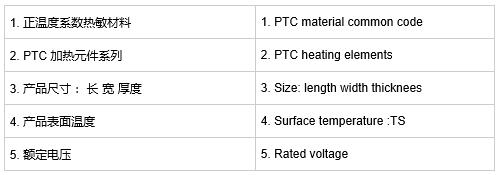

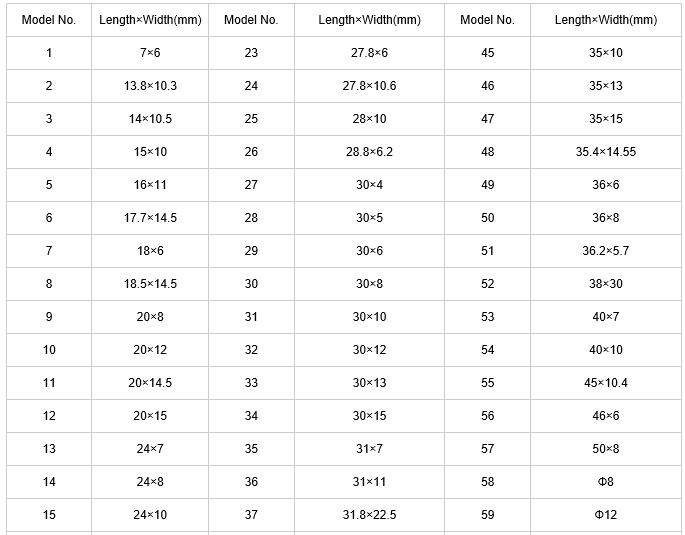

Specifications

Notice:

1.Metallization : Aliuminum (Al) or Silver ( Ag)

2.Curie temperature rang : 25℃~300℃

3.Surface temperature can be selected between: 80℃~310℃

4.Rate voltage: 6V~380V

5.The data of rated resistance which depending on the heating speed and inrush current of PTC elements.

6.The thickness of PTC elements can adjusted into 1.5mm~3.5mm according to customers’ requirements.